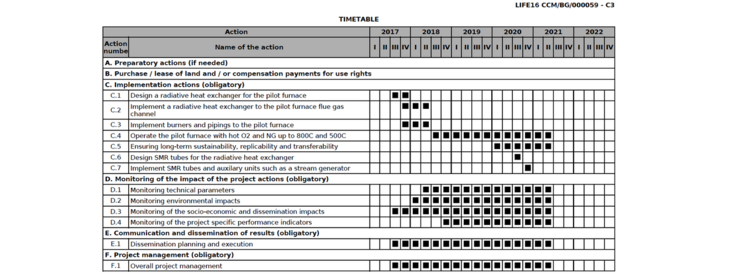

Description of the actions

Project description

Overall, the project team from the Paşabahçe Bulgaria (PB) plant in Targovishte will be in charge of the validation of CleanOx installed to the pilot furnace. In parallel Air Liquide (AL), the technology provider, will conduct in-depth analyses to assess the performance of CleanOx with respect to environmental impact and energy savings. PB will also provide its scientific expertise in tableware glass production.

One of the existing flue gas channels for Eco-HeatOx will be re-engineered by PB to have a flue gas bypass channel, which accommodates a radiative heat exchanger. Based on the available space, a radiative heat exchanger will be designed by AL (Action C.1). The implementation of the bypass flue gas channel and the radiative heat exchanger will be supervised by PB and AL together (Action C.2). The installation of newly design burners has to be performed carefully because the furnace is in operation (Action C.3). After the completion of Phase I (800°C O2 and 500°C NG), SMR tubes will be designed to be installed to the radiative heat exchanger as Phase II (Action C.6). The SMR tubes and a stand-alone auxiliary system such as a boiler will be installed (Action C.7).

Detailed actions

C1 Design a radiative heat exchanger for the pilot furnace:

The aim of the action is to design a radiative heat exchanger, based on available space and flue gas temperature at one side of the flue gas channel at the pilot furnace. This action also involves the design of cold/hot oxygen and natural gas pipings. The capacity of the radiative heat exchanger will be to heat 600Nm3/hr of O2 and 300Nm3/hr of NG up to 800°C and 500°C, respectively. 1x1MW and 1x2MW burners will be operated with the radiative heat exchanger.

C2 Implement a radiative heat exchanger to the pilot furnace flue gas channel:

The main objective of this action is to install the radiative heat exchanger to a newly constructed flue gas bypass channel on one side of the flue gas channel and introduce flue gas the bypass channel to heat up the radiative heat exchanger.

C3 Implement burners and pipings to the pilot furnace:

The main objective of this action is to install newly designed burners which can operate at 800°C O2 and 500°C NG flows. The hot pipings from the radiative heat exchanger to the burners will be also completed.

C4 Operate the pilot furnace with hot O2 and NG up to 800C and 500C:

The main objective of this action is to complete start-up and commissioning followed by daily operation.

C5 Ensuring long-term sustainability, replicability and transferability:

The main objective of this action is to ensure long-term sustainability of project results and to prepare replication of the technology and transfer to results to other industries in order to make the solution proliferate, resulting in greater positive environmental impact.

C6 Design SMR tubes for the radiative heat exchanger:

The main objective of this action is to design SMR tubes for the radiative heat exchanger as Phase II.

C7 Implement SMR tubes and auxiliary units such as a stream generator:

The main objective of this action is to implement SMR tubes to the radiative heat exchanger and steam generator as Phase II.

The aim of this project is to validate and promote CleanOx which can achieve greater reduction in energy and pollutants with significantly lower CAPEX compared to LIFE Eco-HeatOx (1st generation of HeatOx).